Description

Tapped Density Apparatus is a critical instrument used to determine the tapped density of powders and granular materials. Its importance lies in its ability to assess how closely particles pack together when subjected to tapping or vibration. Here’s a concise overview of its use and significance:

Use:

Quality Control: In industries like pharmaceuticals, where dosage uniformity is critical, the tapped density helps ensure consistent product quality. It aids in identifying variations in powder density that might affect the performance and efficacy of formulations.

Material Characterization: Researchers and manufacturers use tapped density data to understand how different materials behave under compaction. This information is crucial for product design and process optimization in various industries, from food to construction.

Granulation Studies: Tapped density measurements are essential for optimizing granulation processes, ensuring the right balance between particle cohesion and flowability in the production of tablets and similar products.

Regulatory Compliance: Regulatory bodies, such as the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), often specify tapped density testing as part of quality control protocols, making the apparatus indispensable for compliance with industry standards.

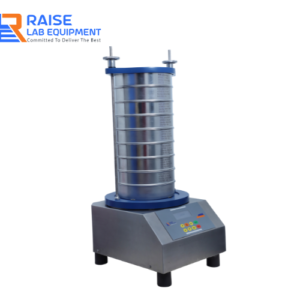

The RTD-2 Tapped Density Apparatus is a cutting-edge instrument meticulously crafted for precise bulk density measurement, adhering to the stringent standards set by various pharmacopoeias, including USP, EP, and ASTM.

Key Features:

Pharmacopoeia Compliance: The RTD-2 adheres to the rigorous standards of USP, EP, ASTM, and other pharmacopeial authorities, ensuring that your density measurements consistently meet regulatory requirements.

User-Friendly Interface: With its intuitive 20×4 LCD display and soft touch membrane keypad, operating the RTD-2 is a breeze. This user-friendly design simplifies data input and retrieval, enhancing operational efficiency.

Efficient Cylinder Holder: The RTD-2 features a cylinder holder with a convenient mechanism for inserting and removing containers. This feature streamlines the setup process, saving you valuable time.

Simultaneous Tapping and Rotation: The apparatus employs simultaneous tapping and rotating actions, ensuring an evenly packed surface during testing. This consistency guarantees accurate and reliable results, enhancing the credibility of your research and quality control processes.

Versatile Graduation Cylinders: The RTD-2 supports both 100ml and 250ml graduation cylinders, catering to the requirements of USP1 and USP2 methods. This versatility allows you to accommodate a wide range of sample sizes.

USP3 Method Support: For USP3 methods, the apparatus includes a 100ml Stainless Steel Measuring Vessel with a Stainless Vessel Cap, providing the versatility needed for density measurements.

Comprehensive Data Analysis: The RTD-2 calculates critical parameters, including un-tapped density, tapped density, Hausner Ratio, and compressibility index in grams per (9/ml), offering deep insights into your materials.

Single and Dual Station Options: Choose between a single station standard configuration or opt for the dual station for increased testing efficiency. The dual station allows you to handle more samples in less time, enhancing productivity.

IQ/OQ Documents: The RTD-2 is equipped with IQ (Installation Qualification) and OQ (Operational Qualification) documents, providing assurance of its performance and reliability.

In a dynamic technological landscape, the RTD-2 stands as a symbol of precision and dependability in bulk density measurement. Embrace the future of pharmaceutical quality control and research with the RTD-2 Tapped Density Apparatus. Its precision, compliance, and adaptability make it an indispensable tool for pharmaceutical laboratories and research facilities.