In the pharmaceutical industry, the integrity of tablet formulations is paramount. One critical aspect of ensuring this integrity is the friability test, which measures a tablet’s ability to withstand mechanical stress during handling, transportation, and storage. Accurate friability testing results are essential for maintaining high-quality standards, preventing product recalls, and ensuring patient safety. In this article, we will explore key process precautions necessary for obtaining accurate friability testing results, the importance of friability testing, and the benefits of using advanced tablet friability testers.

Why Does a Tablet Need Friability Testing?

Have you ever opened a medication bottle only to find crumbled or chipped tablets? Such occurrences are a significant concern in the pharmaceutical industry and can indicate a serious lapse in quality control. Tablets that break easily during transport or handling are not only unsightly but can also lead to inaccurate dosing and efficacy issues.

Friability testing is a standardized method used to assess the mechanical durability of tablets. It measures the tendency of tablets to crumble under mechanical stress. If a tablet is too fragile, it can break apart, leading to compromised medication efficacy and potential safety concerns for patients. Therefore, conducting friability testing is essential to ensure that tablets meet the required standards for strength and durability.

The Importance of Friability Testing

Quality Control: Quality control is critical in the pharmaceutical industry. Tablets must meet stringent guidelines to be considered safe for consumption. Friability testing is a key component of this quality assurance process. By identifying tablets that are prone to breakage, manufacturers can take corrective actions before the product reaches consumers.

Cost-Effectiveness: Tablets that fail friability testing can lead to increased production costs due to wasted materials and the need for rework. By implementing rigorous friability testing, manufacturers can avoid these costs by identifying and correcting issues early in the production process.

Compliance with Regulatory Standards: Regulatory agencies, such as the FDA and EMA, require that pharmaceutical products undergo rigorous testing, including friability testing. Failure to comply with these standards can result in severe penalties, including fines and product recalls. Regular friability testing ensures that products meet regulatory requirements, thereby safeguarding manufacturers from potential legal issues.

Benefits of Equipping a Friability Tester

Investing in a tablet friability tester provides several advantages for pharmaceutical companies:

- Enhanced Quality Control: By utilizing friability testers, companies can ensure that only high-quality tablets are approved for distribution. This helps to maintain a positive reputation in the market.

- Durability Assessment: A friability tester evaluates the durability of tablets, allowing manufacturers to determine whether their products can withstand the rigours of transportation and handling without breaking.

- Research and Development Insights: Friability testers are invaluable tools for researchers. They provide insights into the factors contributing to tablet breakage, allowing for improvements in formulation and binding agents.

- Time and Resource Efficiency: Friability testers streamline the quality control process by testing multiple samples simultaneously, saving time and reducing the need for additional equipment.

Types of Tablet Friability Testers

There are various types of tablet friability testers available, each catering to different testing needs:

1. Single Drum Testers

Single drum testers are ideal for laboratories with lower production volumes. They are generally more affordable and straightforward to operate, making them suitable for smaller pharmaceutical companies or research facilities.

2. Double Drum Testers

Double drum testers are more commonly used in the industry due to their ability to handle multiple samples simultaneously. This feature allows for greater efficiency in the testing process, making it a preferred choice for larger pharmaceutical manufacturers.

3. Triple Drum Testers

Triple drum testers offer even greater capacity and efficiency, allowing labs to test a larger number of samples at once. While they may be more expensive, their efficiency can justify the investment for companies with large production volumes.

Key Process Precautions for Accurate Testing

To ensure accurate friability testing results, laboratories must adhere to specific precautions throughout the testing process:

- Proper Equipment Calibration: Regular calibration of the friability tester is essential to maintain accuracy. Laboratories should use certified weights and follow standard calibration procedures to ensure the device operates within acceptable limits.

- Sample Preparation: Tablets should be prepared according to the manufacturer’s guidelines. This includes ensuring that they are free from dust and debris, which can interfere with test results.

- Standardized Testing Conditions: Consistent environmental conditions are crucial for accurate testing. Laboratories should maintain controlled temperatures and humidity levels to prevent external factors from affecting the results.

- Adherence to Testing Protocols: Laboratories must follow established protocols for conducting friability tests. This includes the number of samples tested, the duration of testing, and the method of evaluating results.

- Data Recording and Analysis: Accurate documentation of test results is vital for quality assurance. Laboratories should maintain comprehensive records of all testing processes and results for future reference and regulatory compliance.

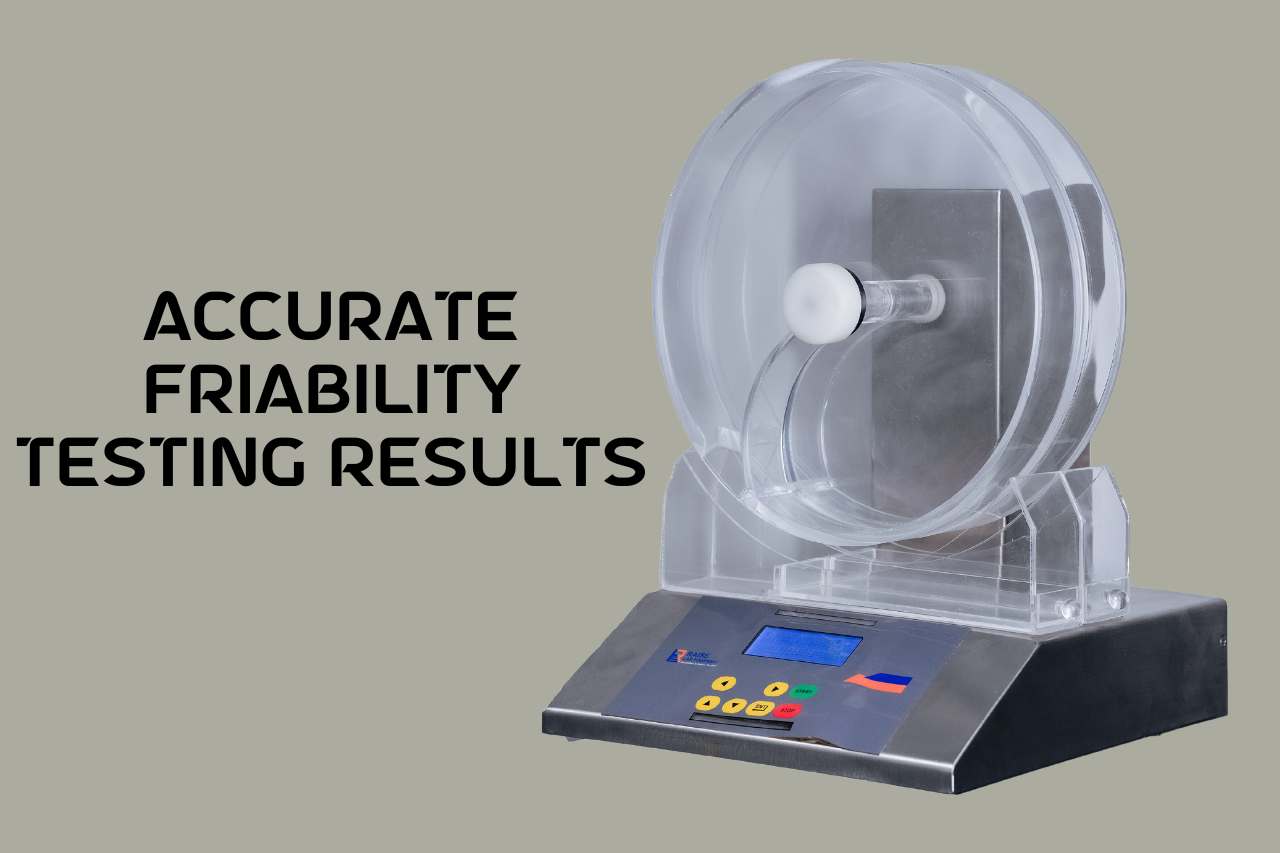

Elevate Your Quality Assurance with the RFT-1 Digital Friability Tester

As pharmaceutical manufacturers strive for excellence in quality assurance, advanced equipment becomes essential. The RFT-1 Digital Friability Tester from Raise Lab Equipment is an innovative solution designed to meet the rigorous demands of modern laboratories.

Key Features of the RFT-1 Digital Friability Tester:

- Precision Engineering: The RFT-1 is meticulously engineered for accuracy and reliability, ensuring that your friability testing processes yield consistent and trustworthy results.

- User-Friendly Interface: Equipped with a digital display and intuitive controls, the RFT-1 simplifies operation, making it accessible for users at all skill levels.

- Multiple Testing Capacity: The RFT-1 can accommodate various sample sizes, allowing for greater flexibility in testing multiple products simultaneously.

- Advanced Reporting Capabilities: This device includes features for generating detailed reports, aiding in compliance with regulatory requirements and internal quality control processes.

- Compliance with International Standards: The RFT-1 meets stringent quality standards, ensuring that your laboratory operations align with both USP and IP guidelines.

Conclusion

Accurate friability testing is crucial for maintaining the integrity and quality of pharmaceutical tablets. By implementing key process precautions and investing in advanced friability testing equipment like the RFT-1 Digital Friability Tester from Raise Lab Equipment, pharmaceutical companies can enhance their quality control processes, ensure regulatory compliance, and ultimately deliver safer, more effective products to consumers. Raise Lab Equipment is committed to providing state-of-the-art solutions that prioritize patient safety and satisfaction, reinforcing its position as a leading source of lab equipment in the pharmaceutical industry.