Introduction

Wet sieve analysis is a critical technique in particle size analysis, especially for materials that are difficult to sieve using dry methods. This process is commonly used in pharmaceuticals, chemicals, and materials science industries to ensure accurate particle size distribution measurements. The electromagnetic sieve shaker is a modern tool designed to enhance the efficiency and precision of wet sieve analysis. This article explores how electromagnetic sieve shakers can revolutionize the wet sieving process, providing detailed insights based on practical applications.

Understanding Wet Sieve Analysis

Wet sieve analysis involves the separation of particles based on their size using a liquid medium. This method is particularly useful for materials that clump together when dry, such as certain powders, slurries, or aggregates.

The key steps in wet sieve analysis include:

- Sample Preparation: To create a slurry, the sample is mixed with a liquid, often water or another suitable solvent. This slurry is then poured over a stack of sieves.

- Sieve Stack Arrangement: A stack of sieves with progressively smaller mesh sizes separates particles based on size. The largest mesh size is at the top, and the smallest is at the bottom.

- Sieving Process: The stack of sieves is subjected to mechanical agitation, which helps separate the particles according to their size. The liquid prevents clogging and facilitates the passage of finer particles through the mesh.

- Analysis and Reporting: After sieving, the material retained on each sieve is collected, dried, and weighed. The data is then analyzed to determine the particle size distribution.

Role of Electromagnetic Sieve Shaker in Wet Sieve Analysis

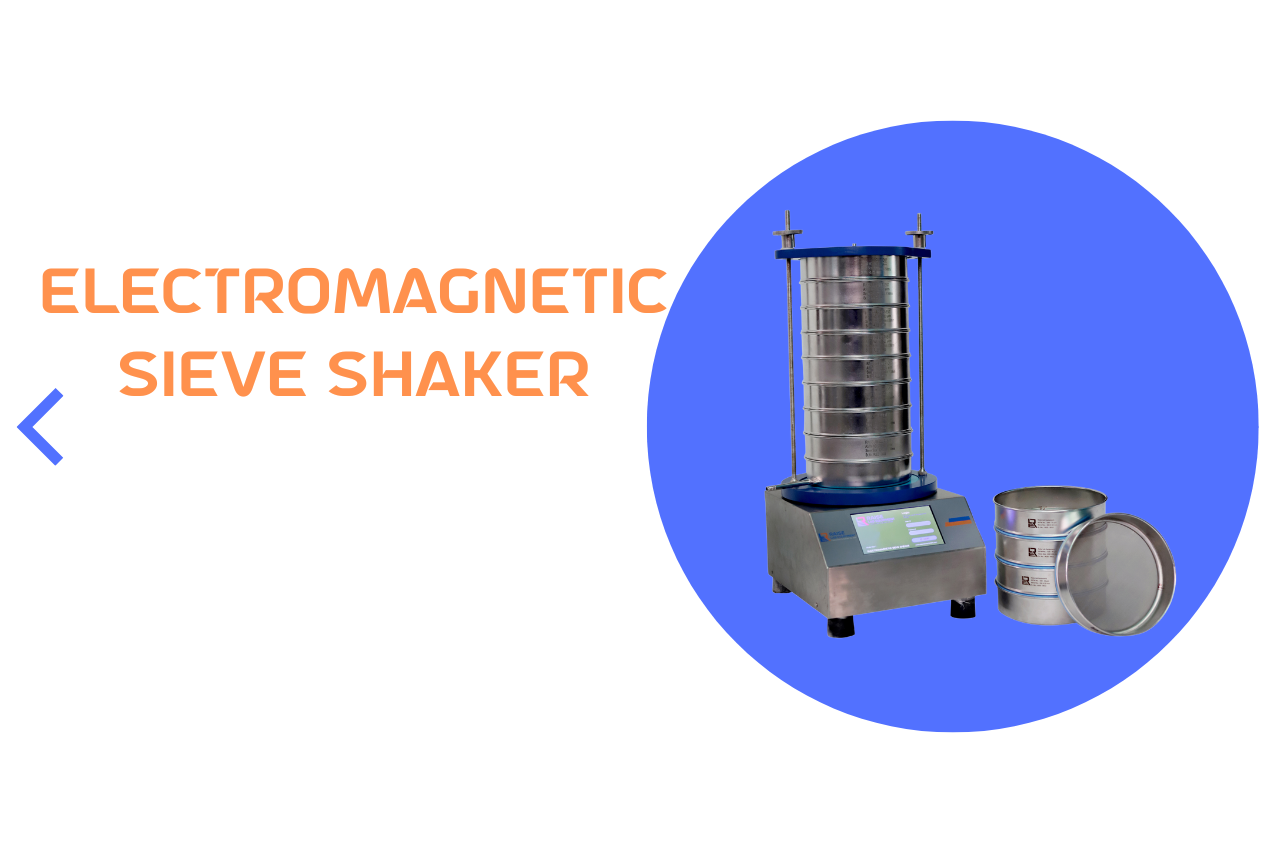

Electromagnetic sieve shakers are advanced devices designed to provide consistent and effective agitation during the sieving process. These shakers use electromagnetic technology to create a controlled, precise shaking motion that enhances the efficiency of wet sieve analysis.

Here’s how electromagnetic sieve shakers contribute to improving the wet sieving process:

Key Features of Electromagnetic Sieve Shakers

- Consistent Shaking Motion: Electromagnetic sieve shakers use an electromagnetic drive mechanism to produce a uniform and controlled shaking motion. This ensures consistent agitation across the entire sieve stack, producing more reliable and reproducible results.

- Adjustable Amplitude and Frequency: The ability to adjust the amplitude and frequency of the shaking motion allows users to customize the sieving process according to the specific requirements of the sample. This flexibility is crucial for optimizing the separation of different particle sizes.

- Reduced Noise and Vibration: Compared to traditional mechanical shakers, electromagnetic sieve shakers operate with minimal noise and vibration. This not only creates a quieter working environment but also reduces the risk of mechanical interference that could affect the accuracy of the results.

- Enhanced Precision: The electromagnetic drive provides precise control over the shaking motion, which helps achieve accurate and repeatable results. This precision is especially important for fine or delicate samples that require careful handling.

- Ease of Use and Maintenance: Electromagnetic sieve shakers are designed for user-friendly operation and low maintenance. The lack of moving parts in the drive mechanism reduces wear and tear, ensuring long-term reliability and minimal maintenance requirements.

Benefits of Using Electromagnetic Sieve Shakers for Wet Sieving

- Improved Separation Efficiency: The uniform and controlled shaking motion produced by electromagnetic sieve shakers enhances particle separation efficiency. This leads to more accurate particle size distribution measurements and better overall analysis.

- Reduced Sample Loss: The precise shaking action minimizes the risk of sample loss or contamination, ensuring that more of the sample is retained for analysis. This is particularly important for valuable or limited samples.

- Faster Analysis Time: Electromagnetic shakers’ consistent and effective agitation speeds up the sieving process, allowing for quicker analysis and turnaround times. This increased efficiency is beneficial in high-throughput testing environments.

- Greater Reproducibility: The precise control offered by electromagnetic shakers ensures that each sieving operation is performed under the same conditions, leading to highly reproducible results. This consistency is crucial for maintaining the quality and reliability of particle size analysis.

- Enhanced User Experience: Elective sieve shakers’ reduced noise, vibration, and maintenance requirements contribute to a more comfortable and user-friendly laboratory environment. This can lead to increased productivity and reduced operator fatigue.

Practical Applications of Electromagnetic Sieve Shakers in Wet Sieving

- Pharmaceutical Industry: In pharmaceutical laboratories, electromagnetic sieve shakers are used to analyze particle sizes of active pharmaceutical ingredients (APIs) and excipients. Accurate particle size distribution is essential for ensuring the proper formulation and performance of pharmaceutical products.

- Chemical Industry: Chemical manufacturers use wet sieve analysis to characterize the particle size of various powders and granules. Electromagnetic sieve shakers help achieve precise measurements, which are critical for product consistency and quality control.

- Materials Science: In materials science research, electromagnetic sieve shakers are employed to analyze the particle size distribution of different materials, including aggregates and composites. This information is valuable for understanding material properties and optimizing processing conditions.

- Environmental Testing: Environmental laboratories use wet sieve analysis to study soil and sediment samples. Electromagnetic sieve shakers facilitate accurate particle size analysis, which is important for assessing soil texture and sediment composition.

Conclusion

Electromagnetic sieve shakers represent a significant advancement in the field of wet sieve analysis. By providing consistent, precise, and efficient shaking motion, these shakers enhance the accuracy and reliability of particle size measurements. Their benefits include improved separation efficiency, reduced sample loss, faster analysis times, and greater reproducibility. Whether in pharmaceutical, chemical, materials science, or environmental testing applications, electromagnetic sieve shakers offer valuable advantages that contribute to the overall quality and efficiency of laboratory analysis. Embracing this technology can lead to more accurate results and a more productive laboratory environment.